SogaWorks is an outstanding one-stop on-demand manufacturing platform to make manufacturing easier. To accelerate innovations for customers, SogaWorks provides machining services from rapid prototyping to mass production, which include CNC Machining, Urethane Casting, Sheet Metal Fabrication, Injection Molding and 3D Printing services. Aiming to achieve better turnaround, more reliable quality and lower cost, SogaWorks builds a distributed collaborative supplier network and creates a digital manufacturing management system with the new technology of AI, IoT, etc.

As an excellent machining service provider, we are cooperating with over 1000 factories with different levels and capabilities, serving over 50,000 customers from 30 countries and regions worldwide since 2015. We continue to empower dispersed manufacturing capacity and build a highly efficient ecological platform for on-demand manufacturing.

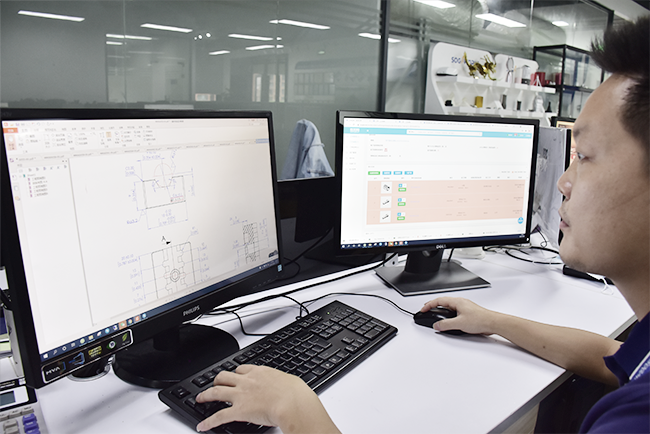

Our account representatives will provide you with professional consultation and quotation services. They will engage in detailed discussions regarding design requirements and delivery schedules, offer feedback on DFM analysis of your parts, and be available throughout the process to address any questions and provide assistance.

Our process engineers possess 5-10 years of practical machining experience. They review every drawing to analyze the manufacturability of your parts, make sure requirements are clearly specified, offer optimization suggestions, and eliminate potential quality issues in advance. Once requirements and designs are confirmed, the engineer will choose appropriate machining processes and equipment that meet the requirements to best machine your pasts.

The project management group will follow the entire part manufacturing process to ensure that the precision requirements of the parts are met, monitor part quality and processing progress and make sure you receive high-quality parts on time. They conduct regular reviews of suppliers' performance to ensure they maintain a high level of manufacturing capability to handle various types of projects.

To ensure that our customers receive high-quality parts, our on-site QA engineers conduct production patrol inspections and final quality checks. Each quality control engineer has years of experience, and they meticulously inspect thousands of parts with precision using industry-standard instruments. They will leave no part uninspected, working diligently to maintain the highest standards.

Make parts machining as easy as online shopping.

To be the largest global on-demand manufacturing platform.

Make manufacturing more intelligent with technology and innovation.

Customer-first, customer satisfaction is the root of our motivation.

We promise to hear our customer’s voices and keep up our efforts to help manufacturing with better turnaround and lower cost.

Honesty is the basis of integrity, sticking to facts and focusing on results.

ISO 14001:2015

ISO 9001:2015

ISO 45001:2018