| Material name | Properties | Best processes | Example parts | |

|

Stainless Steel | Durable, corrosion-resistant, easy-to-sterilize |

CNC machining | Surgical instruments, needles, bone plates, etc. |

|

Titanium | Biocompatible, light-weight, corrosion resistant |

CNC machining | Orthopedic implants, dental fixtures, medical instruments, etc. |

|

Aluminum | Lightweight, corrosion-resistant, machinability |

CNC machining | Wheelchairs, stretchers, and portable medical devices, etc. |

| Silicone Rubber | Biocompatible, flexible, temperature-resistant |

Injection molding, 3D printing | Catheters, oxygen masks, and prosthetic components, etc. |

|

|

Thermoplastics | Biocompatible, sterilization compatibility, durability |

Injection molding, 3D printing | Medical device enclosures, disposable equipment, surgical instruments, etc. |

Ventilator parts

Models for clinical training and surgical planning

Highly variable, low-volume production runs with high-precision

tolerances

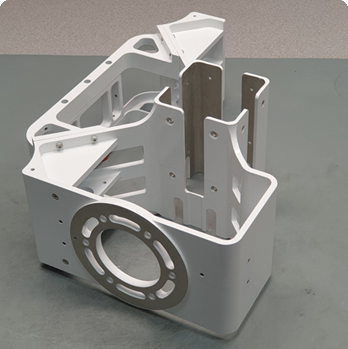

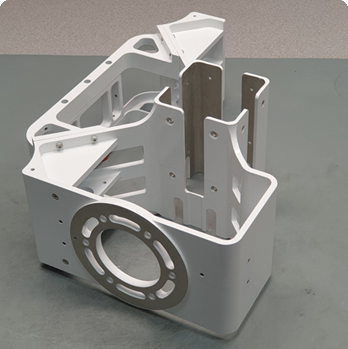

Custom tooling brackets and chassis for medical manufacturing

Rapid prototyping of medical devices using additive manufacturing

Rapid prototyping of medical devices using CNC machining

Custom fixturing

Personal protective equipment (PPE)

| Material name | Properties | Best processes | Example parts | |

|

Stainless Steel | Durable, corrosion-resistant, easy-to-sterilize |

CNC machining | Surgical instruments, needles, bone plates, etc. |

|

Titanium | Biocompatible, light-weight, corrosion resistant |

CNC machining | Orthopedic implants, dental fixtures, medical instruments, etc. |

|

Aluminum | Lightweight, corrosion-resistant, machinability |

CNC machining | Wheelchairs, stretchers, and portable medical devices, etc. |

| Silicone Rubber | Biocompatible, flexible, temperature-resistant |

Injection molding, 3D printing | Catheters, oxygen masks, and prosthetic components, etc. |

|

|

Thermoplastics | Biocompatible, sterilization compatibility, durability |

Injection molding, 3D printing | Medical device enclosures, disposable equipment, surgical instruments, etc. |

Anodizing in medical improves the corrosion resistance and wear resistance of medical components.

Passivation enhances the corrosion resistance and ensures durability and biocompatibility of medical components.

Electropolishing straightens the surface and avoids bacterial adhesion.

Powder coating provides durable, hygienic, and visually appealing finishes and contributes to infection control and long-term functionality.

Ventilator parts

Models for clinical training and surgical planning

Highly variable, low-volume production runs with high-precision tolerances

Custom tooling brackets and chassis for medical manufacturing

Rapid prototyping of medical devices using additive manufacturing

Rapid prototyping of medical devices using CNC machining

Custom fixturing

Personal protective equipment (PPE)