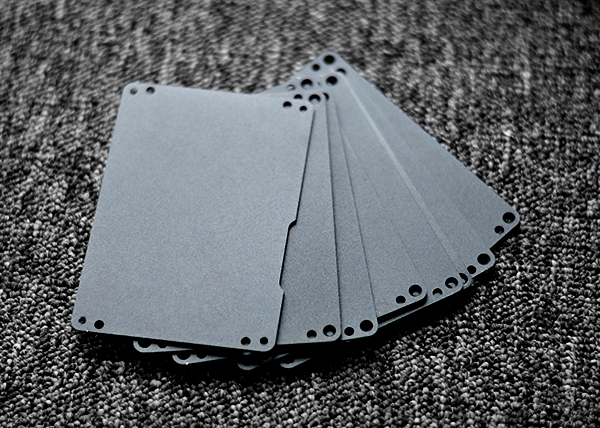

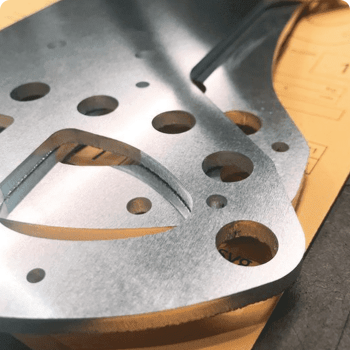

| Dimension Detail | Tolerance |

| Hole sizes | ±0.005" |

| Edge to edge, single surface | ±0.010" |

| Edge to hole, single surface | ±0.010" |

| Hole to hole, single surface | ±0.005" |

| Bend to edge / hole, single surface | ±0.015" |

| Bend to Bend | ±0.020" |

| Edge to feature, multiple surface | ±0.030" |

| Over formed part, multiple surface | ±0.030" |

| Bend anglev | ±1° |

30+ countries and regions

50,000+ customers

16,000,000+ parts manufactured in total

1,000+ collaborative partner factories

4,800+ precision equipment

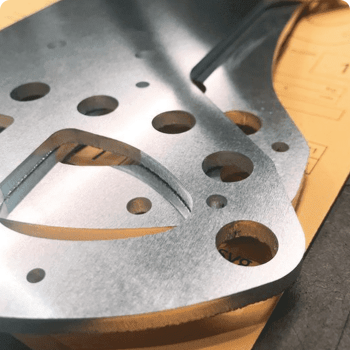

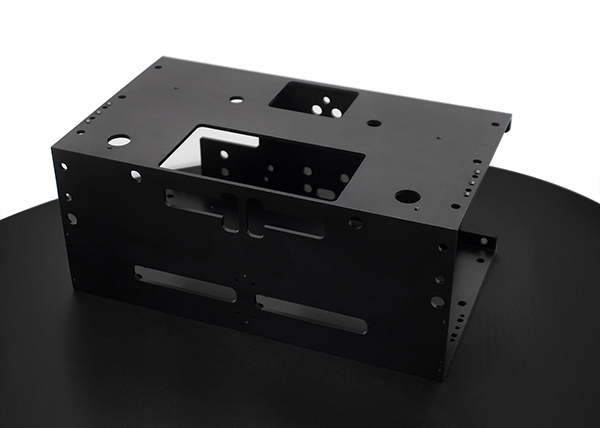

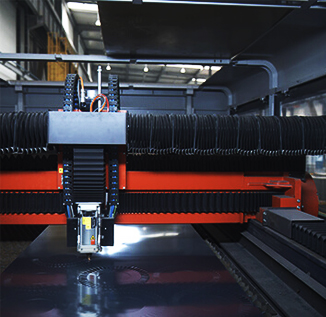

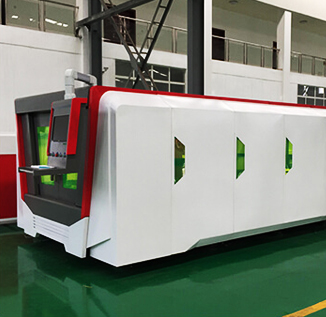

CNC Laser Cutting

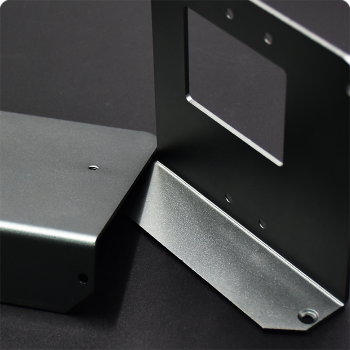

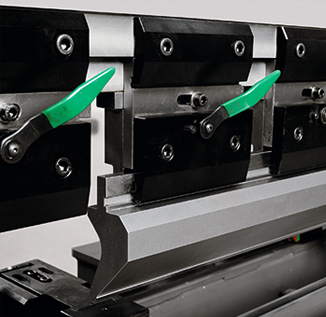

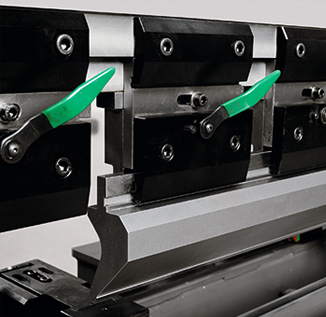

CNC Bending Machine

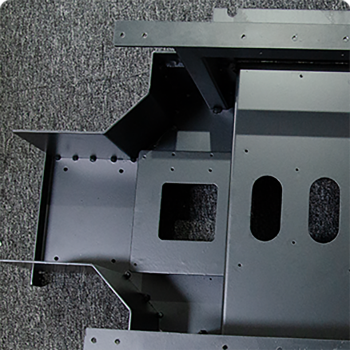

Angle Bending Process

Profiled Bending Process

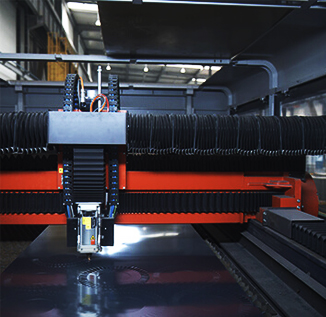

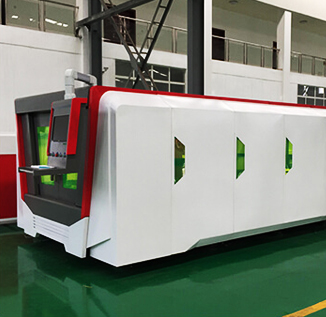

CNC Laser Cutting

CNC Bending Machine

CNC Fiber Laser Cutting Machine

Quick Online Quotation

Combining bending, laser cutting with machine learning-driven technologies, we can offer rapid quotations for your inquiry. Accelerating project initiation for your sheet metal needs.

Fast Lead Times

With our strong network of qualified manufacturing shops, we provide quick pricing and completed parts as fast as 3 days.

Scalable Volume

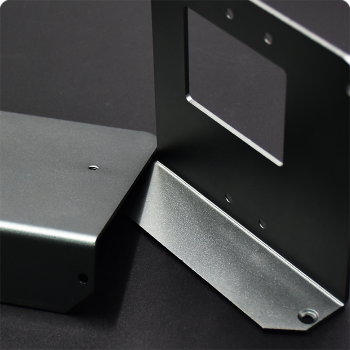

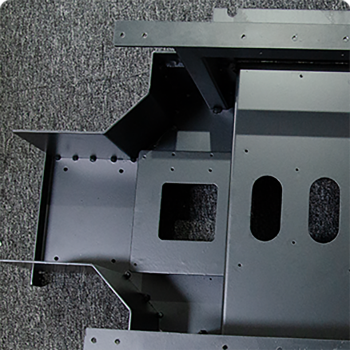

We custom fabricate all sheet metal parts as per your requirements, offering a cost-effective setup compared to CNC machining. Whether you need just a single prototype or more, our service is suitable for you.

Online Engineering Support

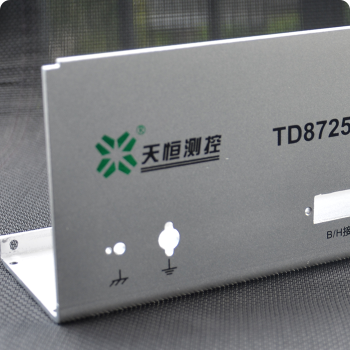

Enjoy hassle-free services with our engineering report. Our sheet metal engineers ensure the precision and high quality of your project, reducing your workload and checking the product quality.

Press Riveting, Welding, etc

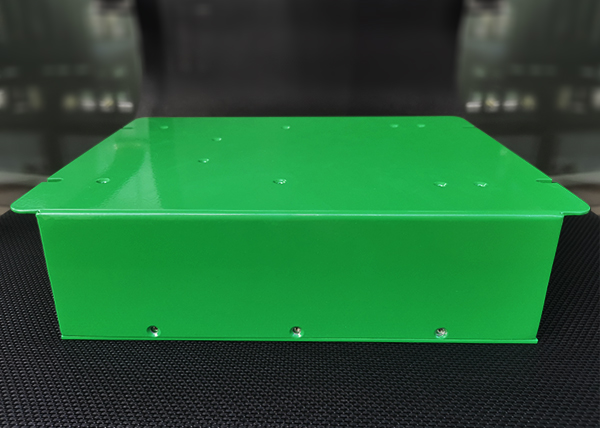

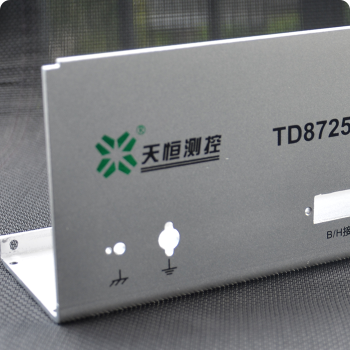

Baking Finishing, Plastic Spraying, Electroplating, etc

| Dimension Detail | Tolerance |

| {{ item.name }} | {{ item.standard_m }} |

30+ countries and regions

50,000+ customers

16,000,000+ parts manufactured in total

1,000+ collaborative partner factories

4,800+ precision equipment

CNC Laser Cutting

CNC Bending Machine

Angle Bending Process

Profiled Bending Process

CNC Laser Cutting

CNC Bending Machine

CNC Fiber Laser Cutting Machine

Quote in 5 Seconds

Utilizing a self-developed, machine learning-driven intelligent quoting system, we can offer rapid quotations for your inquiry in 5s.

One-Stop Manufacturing Service

We provide one-stop manufacturing services from R&D prototypes to massive production, covering hundreds of materials and most of the surface finishes.

End-to-end professional Service

Our specialized account managers and engineers provide “One to One” service, and work collaboratively with both customers and partners by better understanding their requirements, which is to achieve better turnaround time and lower cost for your project.

Fully Inspected Before Delivery

Before shipping out the parts to you, we conduct a strict final inspection for all parts with high-accuracy measuring equipment.