30+ countries and regions

50,000+ customers

16,000,000+ parts manufactured in total

1,000+ collaborative partner factories

4,800+ precision equipment

Injection Molding

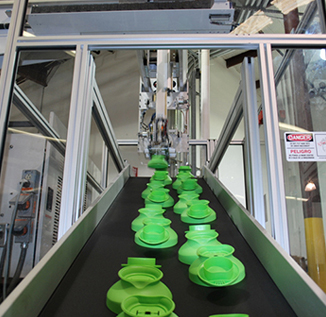

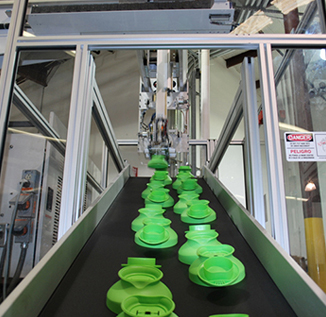

Injection Molding Parts

Polishing Of Injection Mould

Injection Molding Workshop

Plastic Shredder

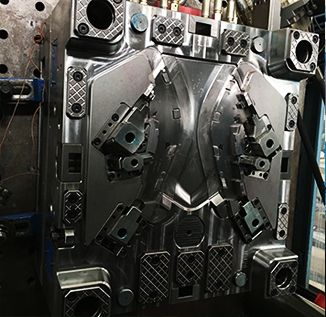

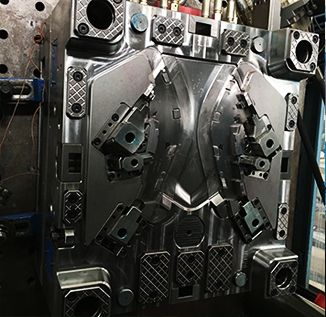

Mould In Injection Molding

Vertical Injection Molding Machine

Color Injection Molding Machine

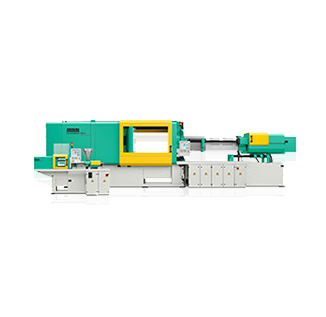

400T-High Precsion Injection

Molding Machine

130T-High Precsion Injection

Molding Machine

200T-High Precsion Injection

Molding Machine

Horizontal Elbow Injection

Molding Machine

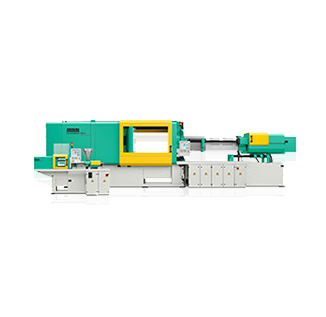

Krauss Injection Molding Machine

Rainbow Injection Molding Machine

250T-High Precsion Injection

Molding Machine

One-stop Service

We provide injection molding services from R&D prototypes to large-volume production, covering extensive materials and multiple surface finishes. Get your parts delivered right to your door without the hassle of project management, logistics, or shipping.

Fast Turnaround

We reduce your product development cycle and bridge to production with injection-molded parts as fast as 2 weeks, even less.

Design Optimization

Once we get your request for injection molding, our experts in mold tooling and injection molding will take a close look at your molded parts and Provide DFM feedback within 24 hours.

Strong Network

We are ISO9001:2015, ISO 14001 certified. We have built up a strong and efficient network of qualified shops, only top-notch shops that apply to become our suppliers can pass the qualification process.

30+ countries and regions

50,000+ customers

16,000,000+ parts manufactured in total

1,000+ collaborative partner factories

4,800+ precision equipment

Injection Molding

Injection Molding Parts

Polishing Of Injection Mould

Injection Molding Workshop

Plastic Shredder

Mould In Injection Molding

Vertical Injection Molding Machine

Color Injection Molding Machine

400T-High Precsion Injection

Molding Machine

130T-High Precsion Injection

Molding Machine

200T-High Precsion Injection

Molding Machine

Horizontal Elbow Injection

Molding Machine

Krauss Injection Molding Machine

Rainbow Injection Molding Machine

250T-High Precsion Injection

Molding Machine

Quote in 5 Seconds

Utilizing a self-developed, machine learning-driven intelligent quoting system, we can offer rapid quotations for your inquiry in 5s.

One-Stop Manufacturing Service

We provide one-stop manufacturing services from R&D prototypes to massive production, covering hundreds of materials and most of the surface finishes.

End-to-end professional Service

Our specialized account managers and engineers provide “One to One” service, and work collaboratively with both customers and partners by better understanding their requirements, which is to achieve better turnaround time and lower cost for your project.

Fully Inspected Before Delivery

Before shipping out the parts to you, we conduct a strict final inspection for all parts with high-accuracy measuring equipment.